b l o g

s e p t e m b e r 2 0 2 1

By Piero Bianchessi, Former Owner and Operator of Venui Vanilla

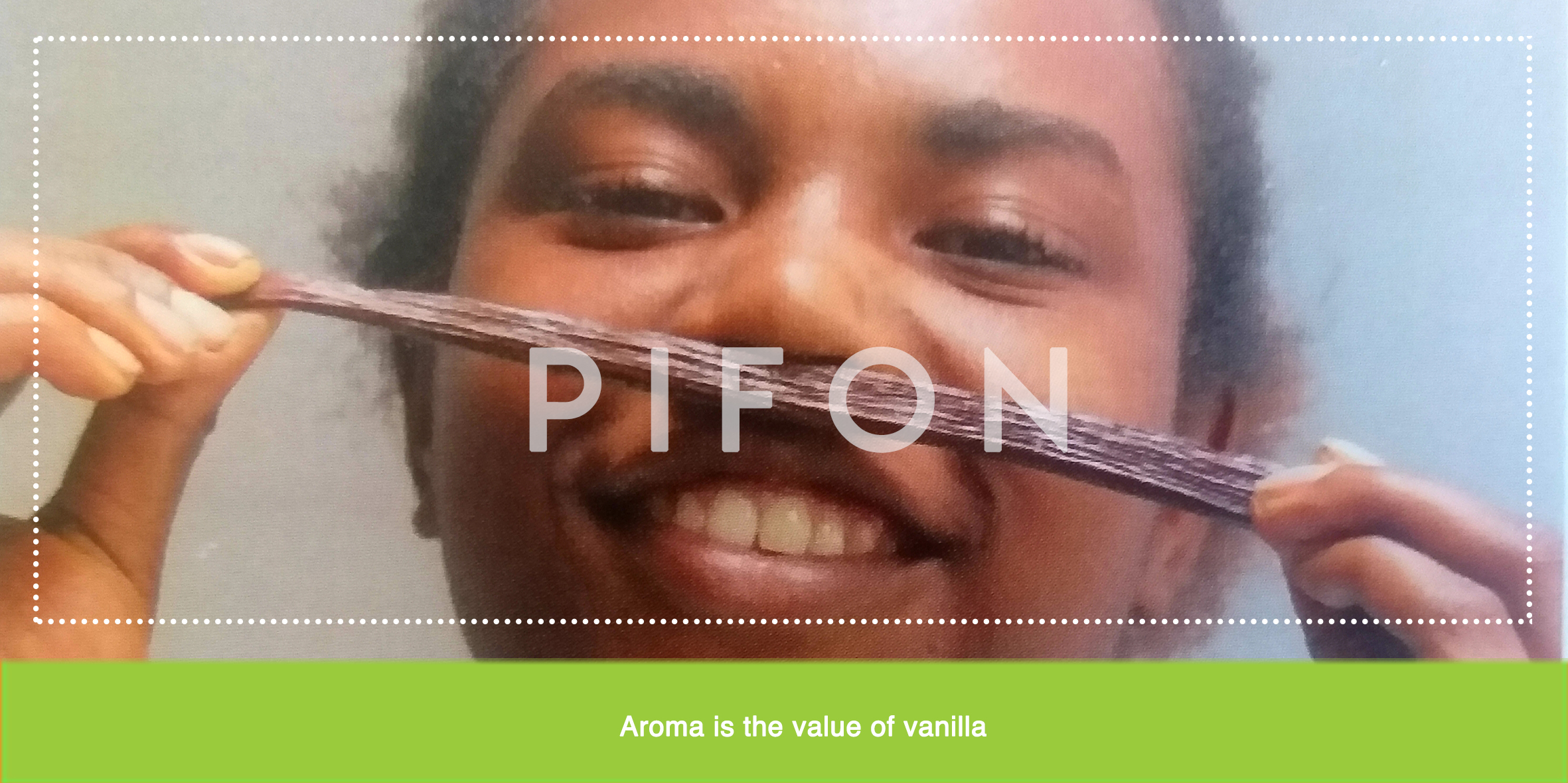

At harvest the green-ripe vanilla beans have very little aroma.

To create the aroma you must ‘cure’ the beans. Vanilla beans have zero market value unless you cure them – the value of the vanilla is its aroma. Curing is not a drying process – it is a careful process involving fermentation, sweating and slow drying. The main component responsible for the aroma called ‘vanillin’.

The vanilla develops a ‘sugar’ called glucovanillin during the last few days of ripening. During the fermentation process glucovanillin will split into glucose and vanillin. The glucose is the ‘sticky/oily’ component that preserves the vanilla and the vanillin provides the aroma.

Important

The riper the vanilla, the higher the glucovanillin content; after fermentation the beans will have a higher glucose and vanillin content, and a higher market value.

Curing vanilla is specialised and we advise neighbouring farmers to consider investing in a co-operative curing centre operated by a trusted and experienced curer. Many inexperienced solo farmers have wasted their vanilla crop through mistakes made during the curing process, i.e. destroying the vanilla aroma by drying the beans too quickly.

Enzymatic Overview

- (1) A ‘sugar’ develops inside the ripening vanilla beans called GLUCOVANILLIN.

- (2) An ENZYME is responsible for the transformation (fermentation) of glucovanillin into;

- a. ‘glucose’ (the preservative component) and b. ‘vanillin’ (the aromatic component)

- (3) NO aroma will develop from the curing of green, unripe vanilla.

Curing Points

- (1) The beans must be harvested only at the ‘blossom-end yellow’ stage of the bean.

- (2) The curing process must start within 24 hours after the harvest, or the beans will develop ‘off’ smells impossible to eliminate.

- (3) The aromatic component will develop only with a slow and moist curing-fermentation process.

- (4) Glucose is responsible for the oily-sticky look of the beans, and it is very important for the preservation of the beans.

- (5) A bean with high glucose content will be stable (i.e. mould free) at 25% moisture content – the vanilla will be heavier, will look nice and plump, and the farmer will make more money.

- (6) A bean with low glucose content will hold quickly even when over dried (10% moisture content).

- (7) If the sun curing process is too fast it will kill the enzyme and destroy the aroma.

- (8) For correct enzymatic activity keep the beans at the right temperature and humidity for the right amount of time to maximise the vanillin content.

- (9) A small volume (for farmers and curers handling relatively small quantities of vanilla) of beans have a low thermal inertia and will quickly lose the heat aqcuired during the water scalding or sun-sweating process to the detriment of the enzymatic activity. Throughout the curing technique section in this vanilla technical session, special emphasis is given to the importance of keeping beans warm overnight.

- (10) A blanket in contact with the beans will soak up all the ‘sweating’ and the glucose produced by the fermentation. Using cut-to-size clear plastic sheets will avoid this problem.

The Value of Curing Centres

- (1) The ‘CURER’ must be a specialised person; neighbour farmers should select one trusted ‘specialised’ curer and centralise the curing equipment and cost.

- (2) When curing a large quantity of vanilla, the curing centre will be able to purchase better curing equipment.

- (3) It is in the interest of the curer to cure a large amount of beans, fully dedicating their time and expertise to the task.

- (4) An experienced curer understands the curing process involved and the market requirements that demands beans with high vanillin content.

- (5) The minimum quantity of vanilla for each curing centre should be at least 400kg of green vanilla each season.

‘Killing’ Methods

In this vanilla technical session, the ‘killing’ method refers to killing the vegetative life in the vanilla pod to stop Vanilla planifolia dehiscence (the beans splitting). Vanilla tahitensis is not dehiscent (does not split) and therefore this killing is not necessary.

Over-split vanilla will fetch a lower price in the market. Killing the Vanilla planifolia bean is achieved by raising the whole bean’s temperature above 60°C and maintaining it between 60°C and 68°C.

This may be achieved by two methods:

- (1) water-killing (the bourbon method) – using a hot water treatment

- (2) sun-killing – exposing the beans, wrapped in clear plastic sheets, to the sun.

The excellent side effect of using the water-killing method for both Vanilla planifolia and Vanilla tahitensis – is it greatly improves the enzymatic activity. There are no contraindications to the use of the water-killing for Vanilla tahitensis.

Important

The sun killing method is viable only in countries with a very well defined dry season. In less sunny areas sun killing may require a dew consecutive days of sun exposure, during which period the beans will keep splitting.