b l o g

o c t o b e r 2 0 2 1

By Piero Bianchessi, Former Owner and Operator of Venui Vanilla

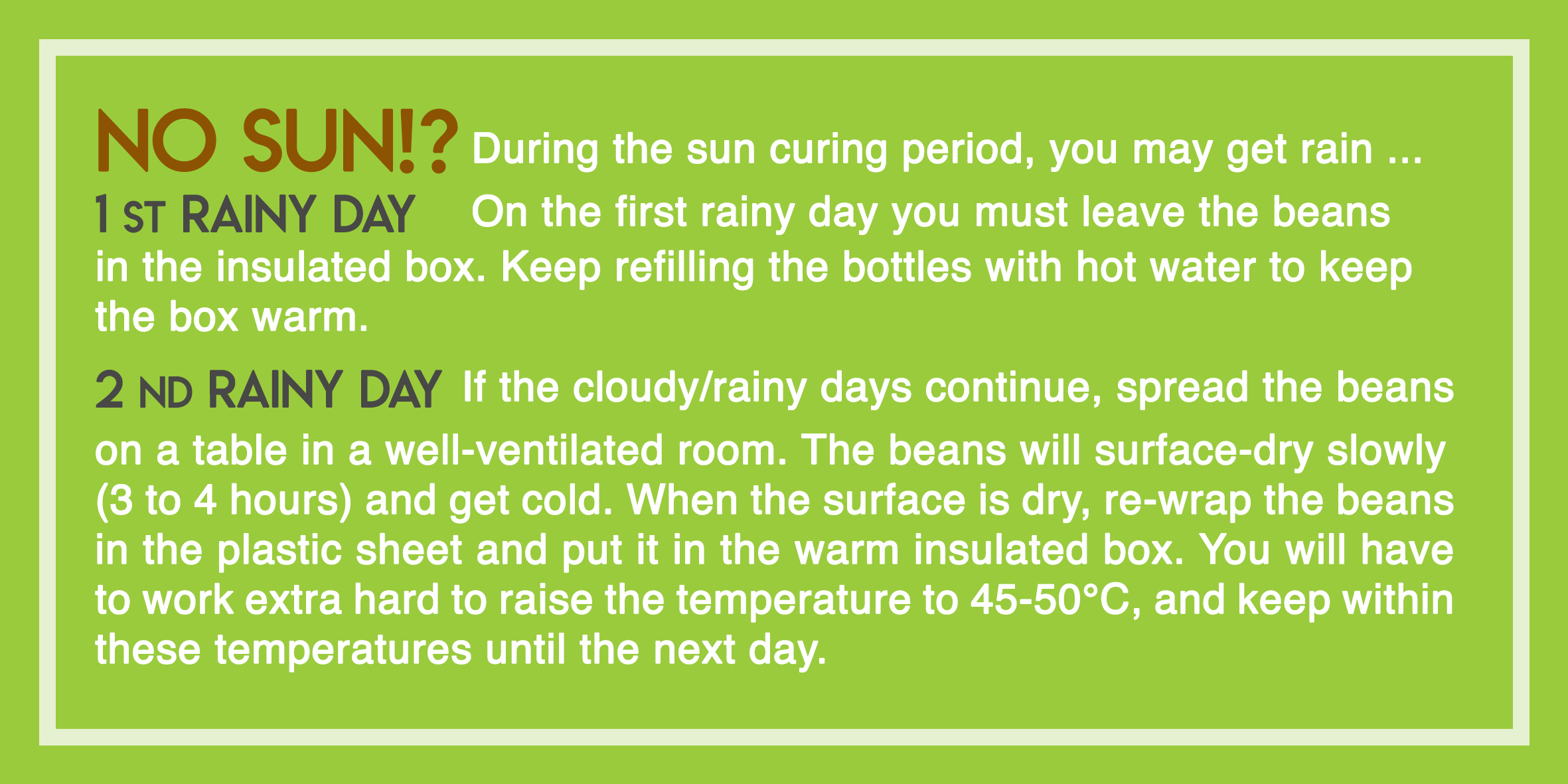

Goal 1 : to avoid mould by drying slowly everyday

Goal 2 : to increase enzymatic activity by sweating

Goal 3 : to continue enzymatic activity by keeping warm overnight

Warning : Do not touch the beans with your hands; handling the beans with your bare hands will contaminate the beans and reduce their quality. Use the plastic to hold and move them.

Tools : (1) a long bamboo table (2) insulated box (sweating box) (3) clear plastic sheets

Process

(1) After 48 hours of IN-BOX STARTING remove the beans.

(2) In the sun, unwrap the beans from the plastic and lay out to dry.

(3) As soon as the beans are surface-dry (1-2 hours), rewrap them in plastic and leave in the sun to sweat.

(4) When the sun is no longer hot store the hot beans in the insulated box to keep warm overnight.

Repeat the process for 12 to 15 days until the beans moisture reaches 50%. Then the beans are ready for IN-SHED CURING.

Warning : Do not try to speed up the drying of the beans. If you do you will limit the enzymatic activity, and your beans will have poor vanillin content = low value.

Problem

Beans have over-dry split ends.

Answer

Bind the split ends of the beans together into a bunch to avoid over-drying.

Moisture reduction takes approximately 2 weeks